Hello:

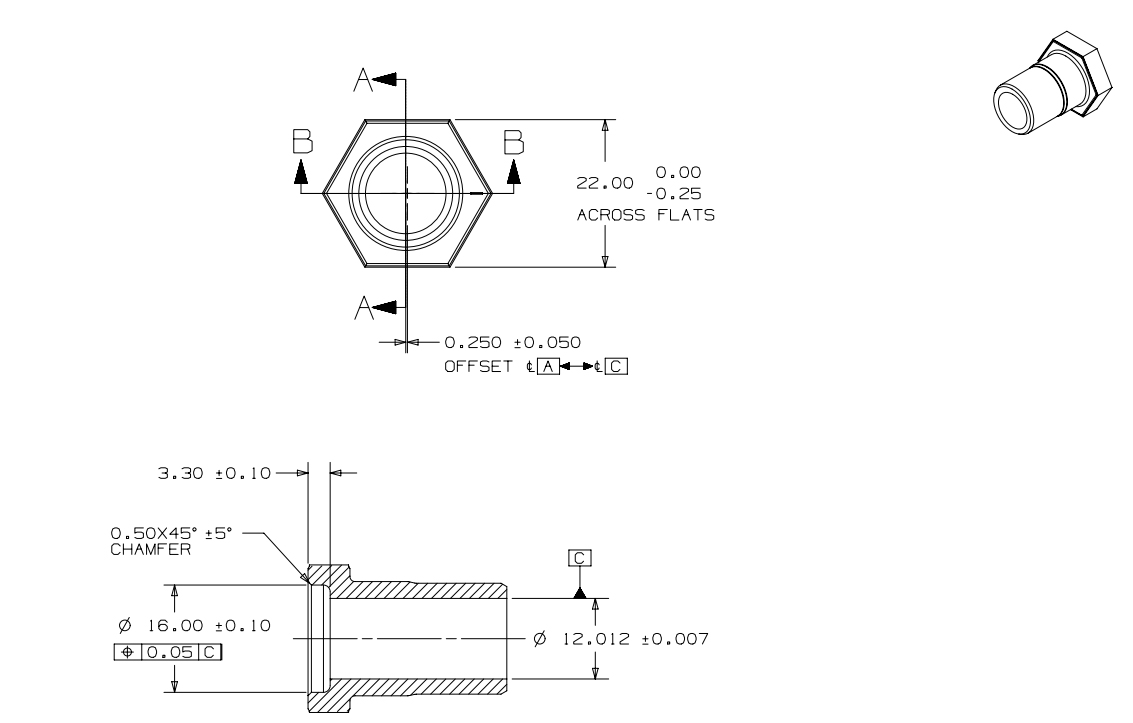

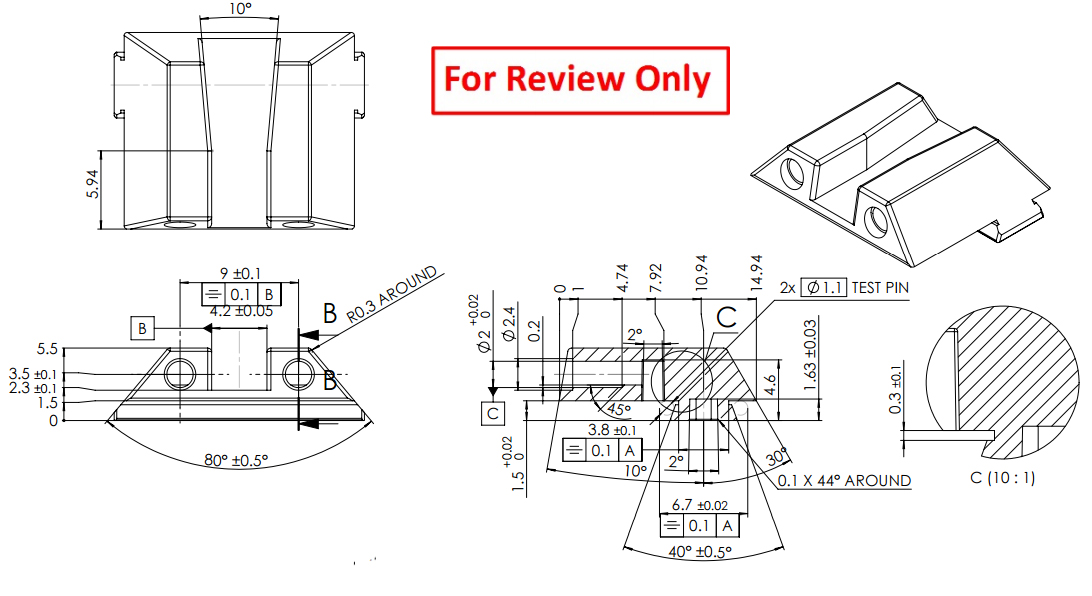

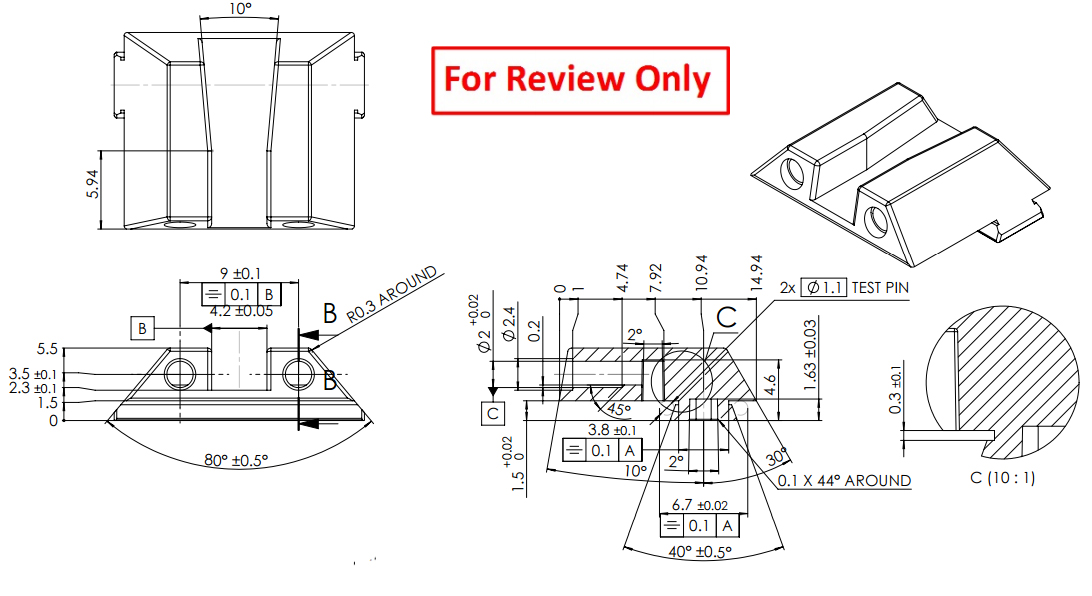

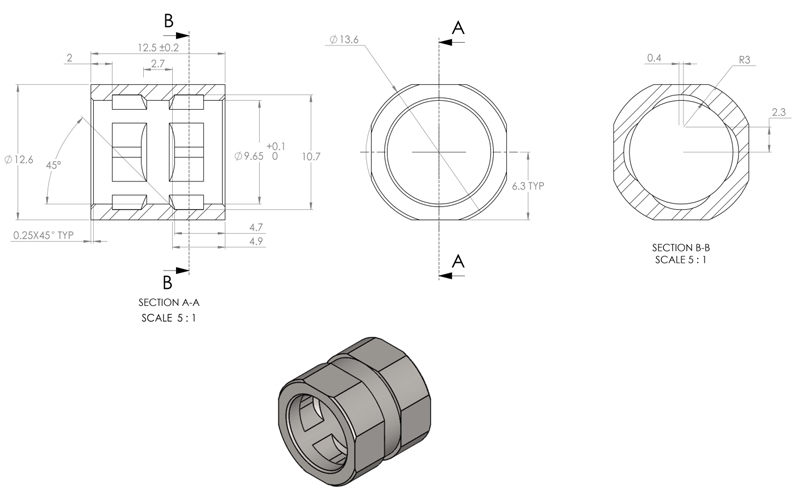

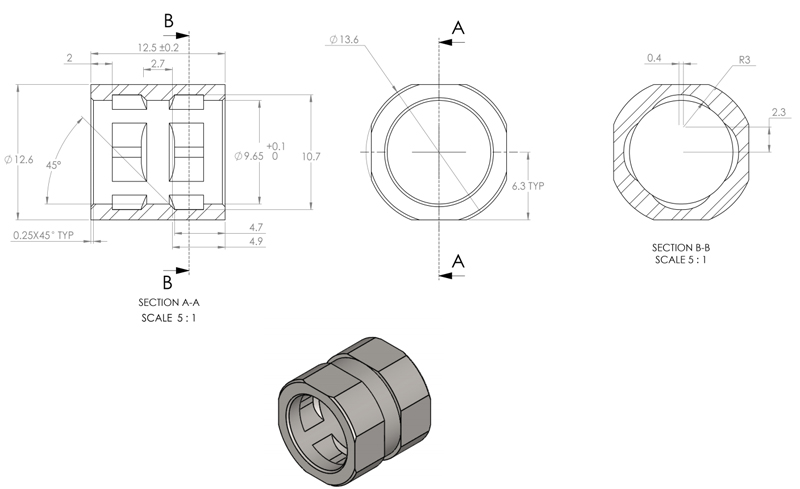

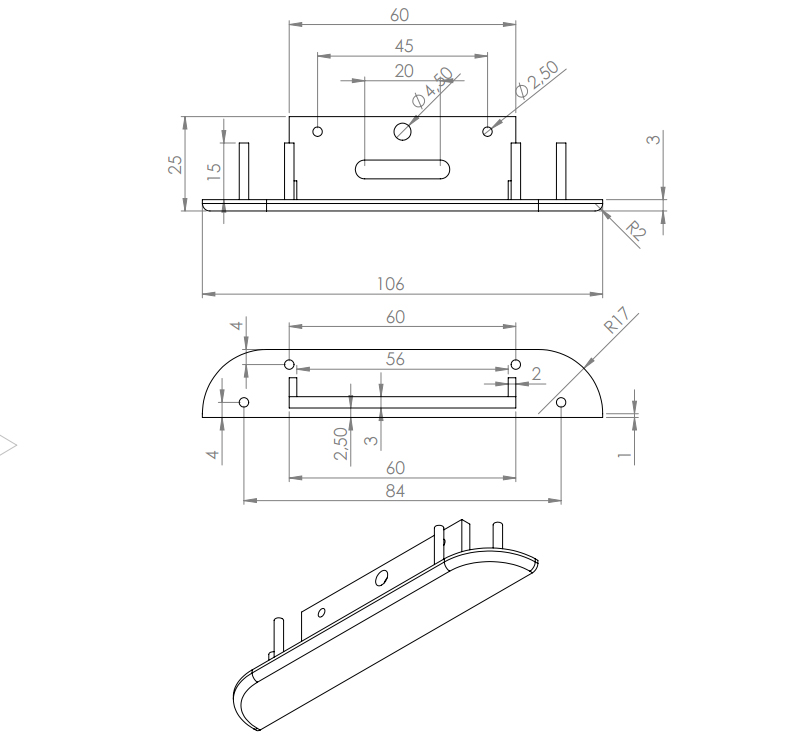

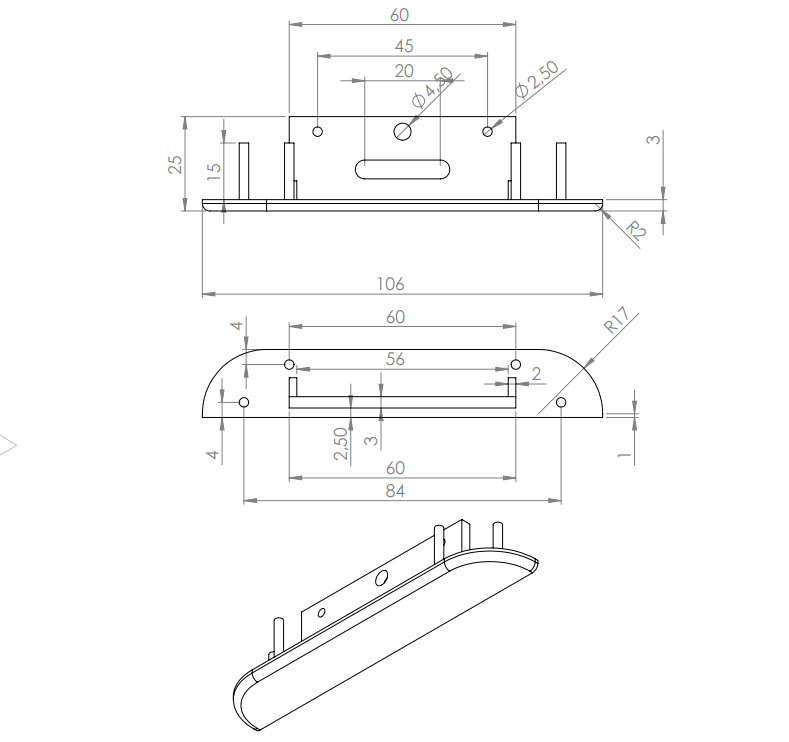

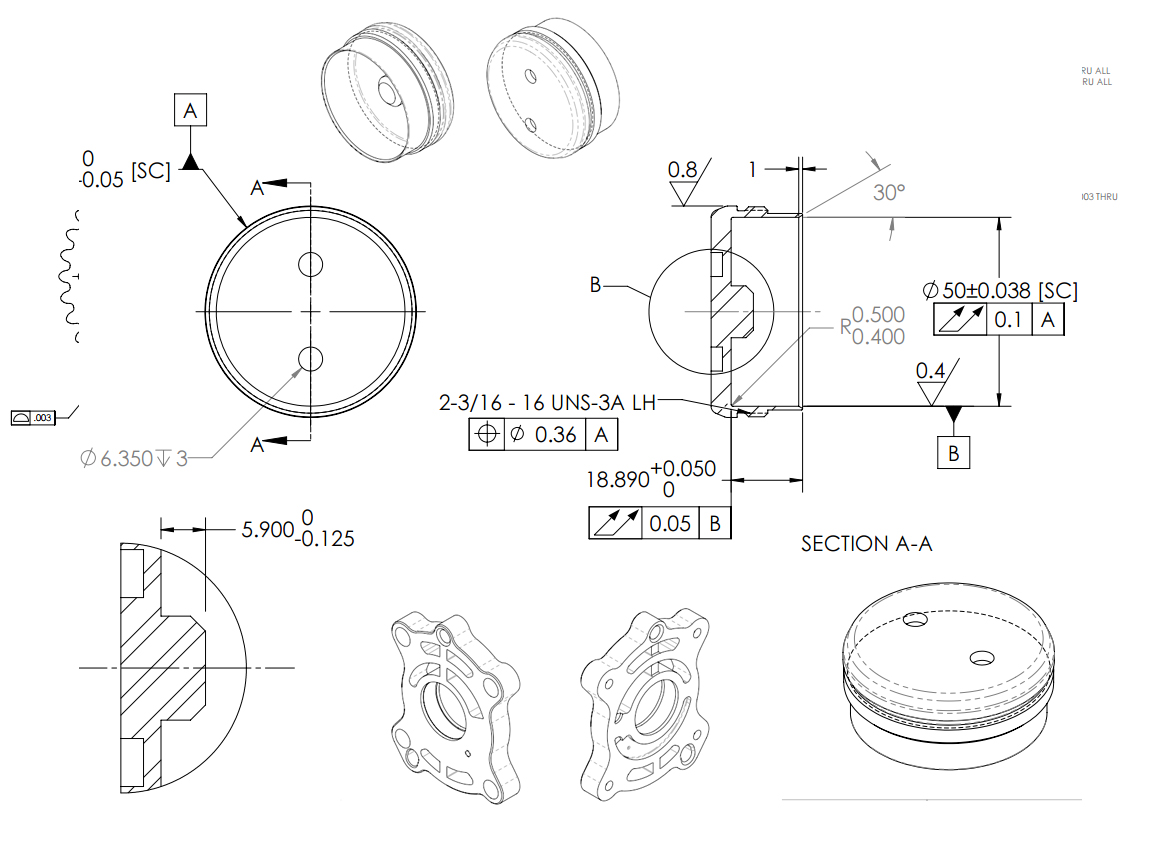

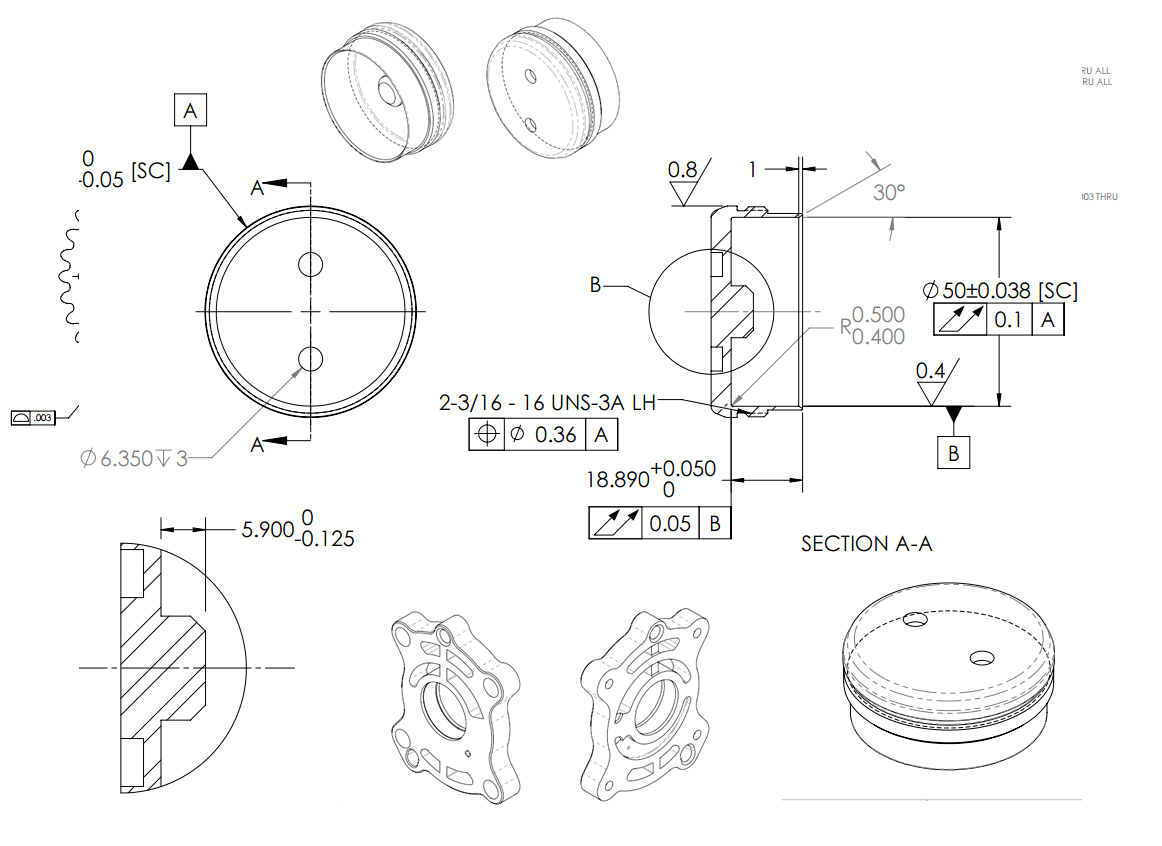

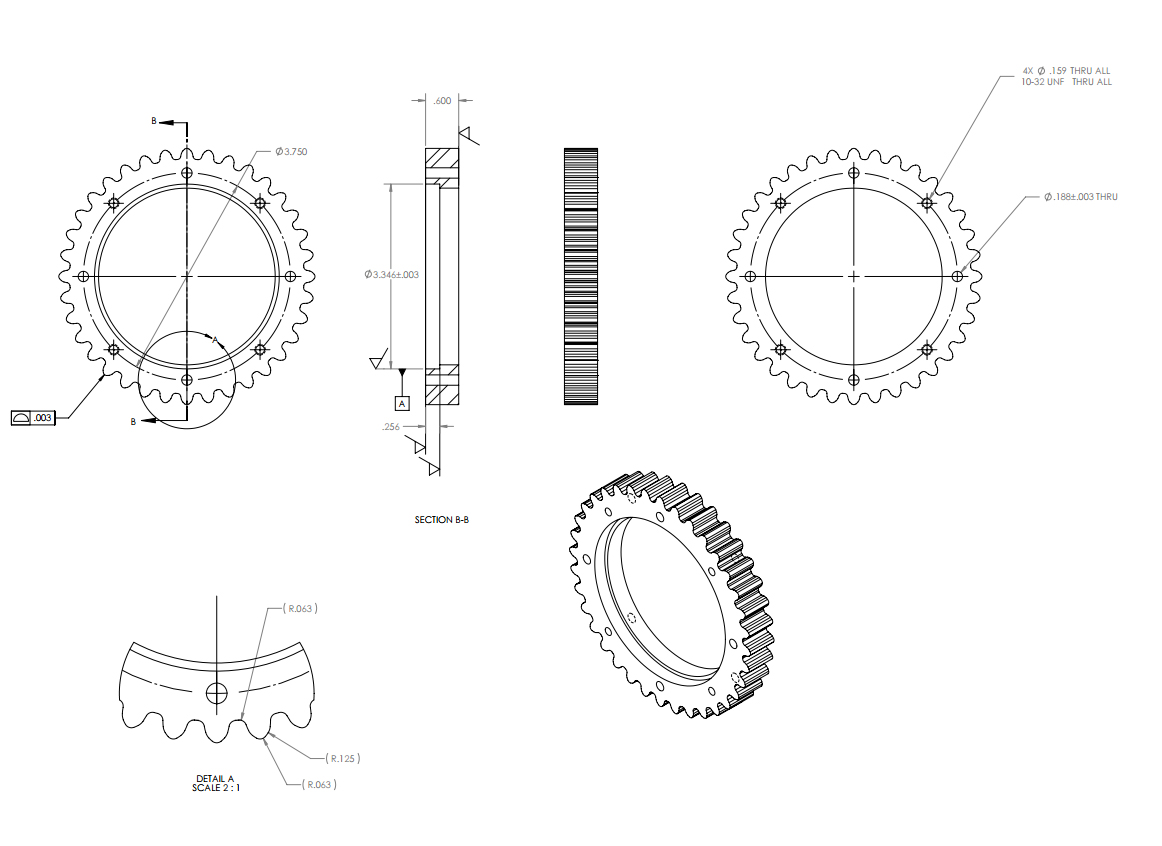

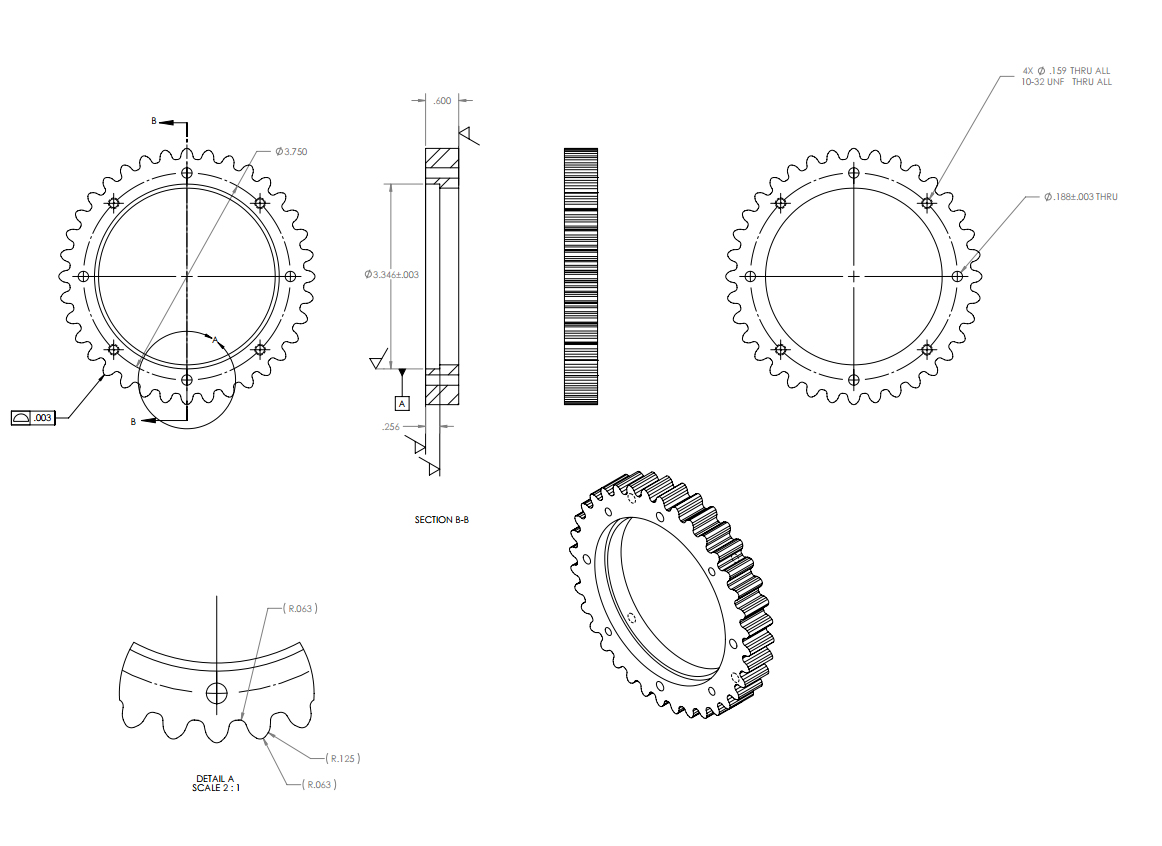

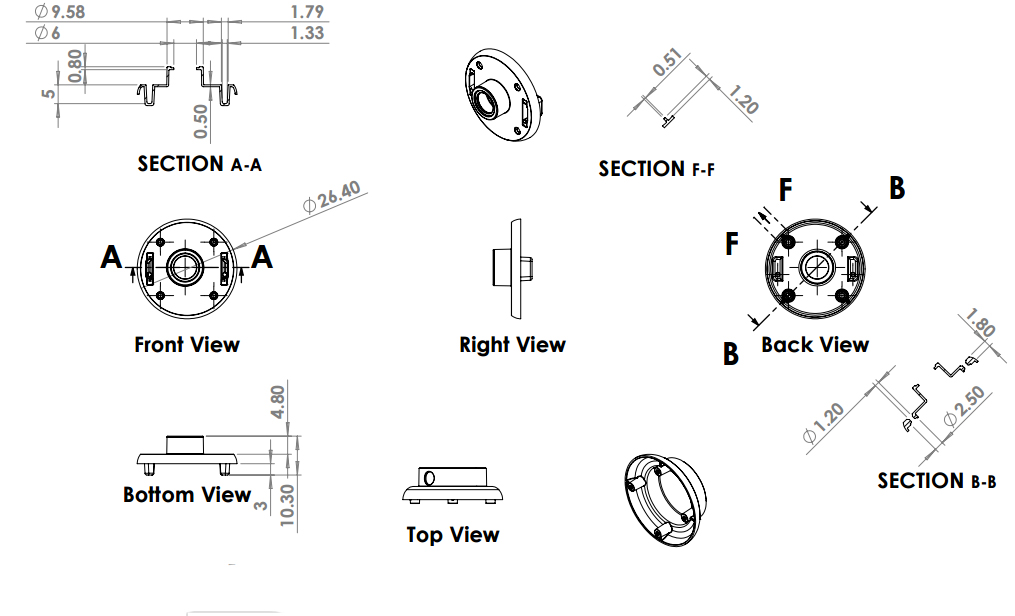

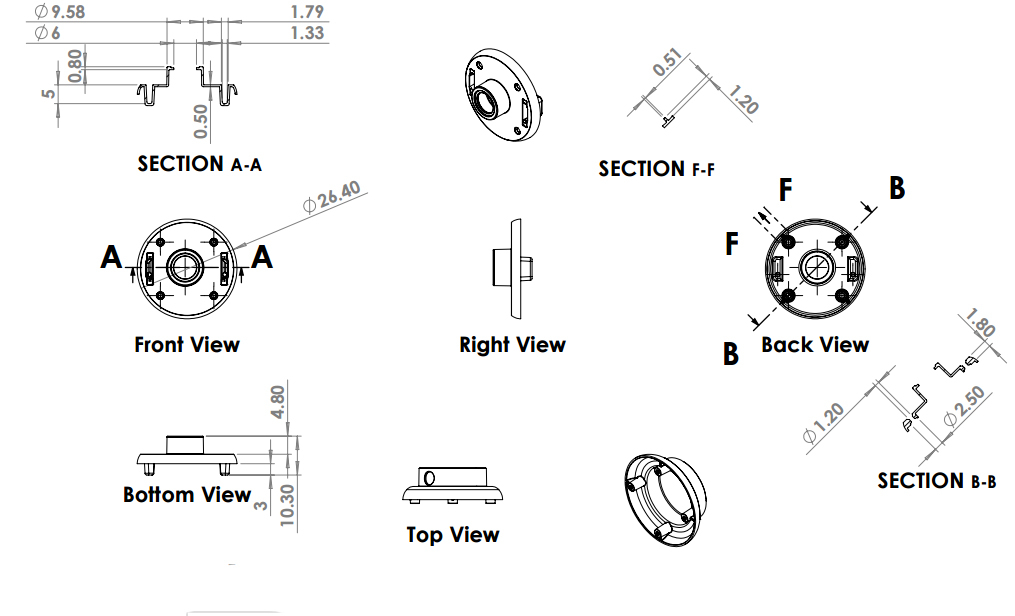

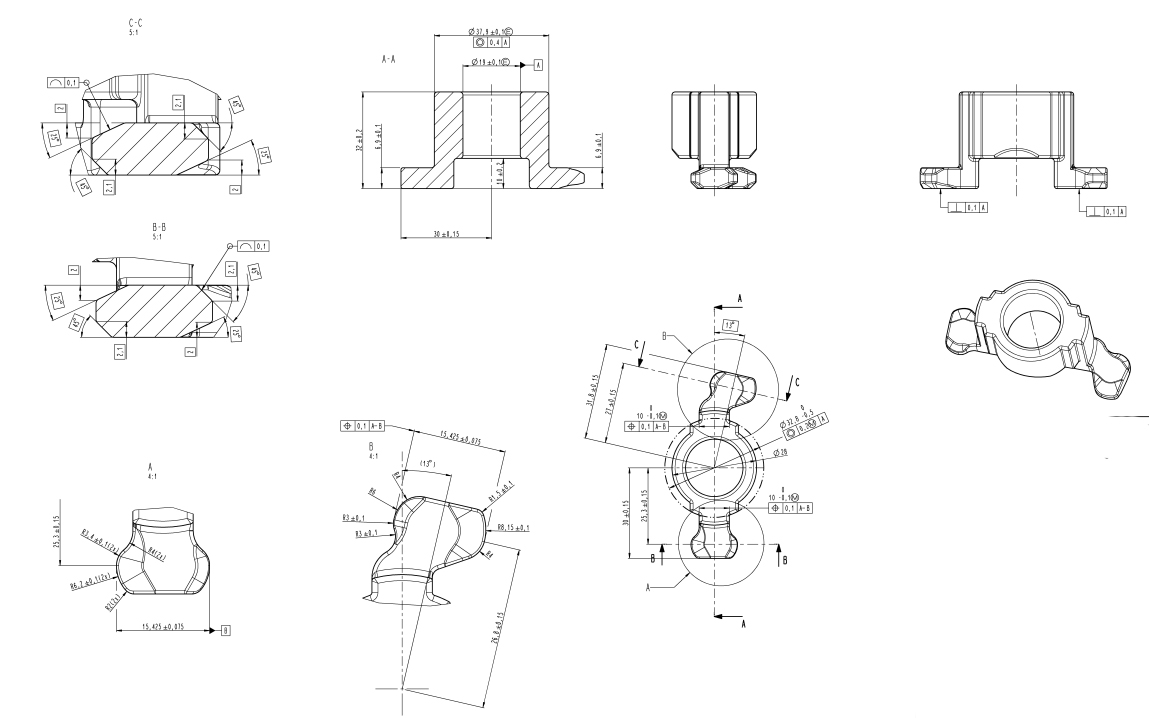

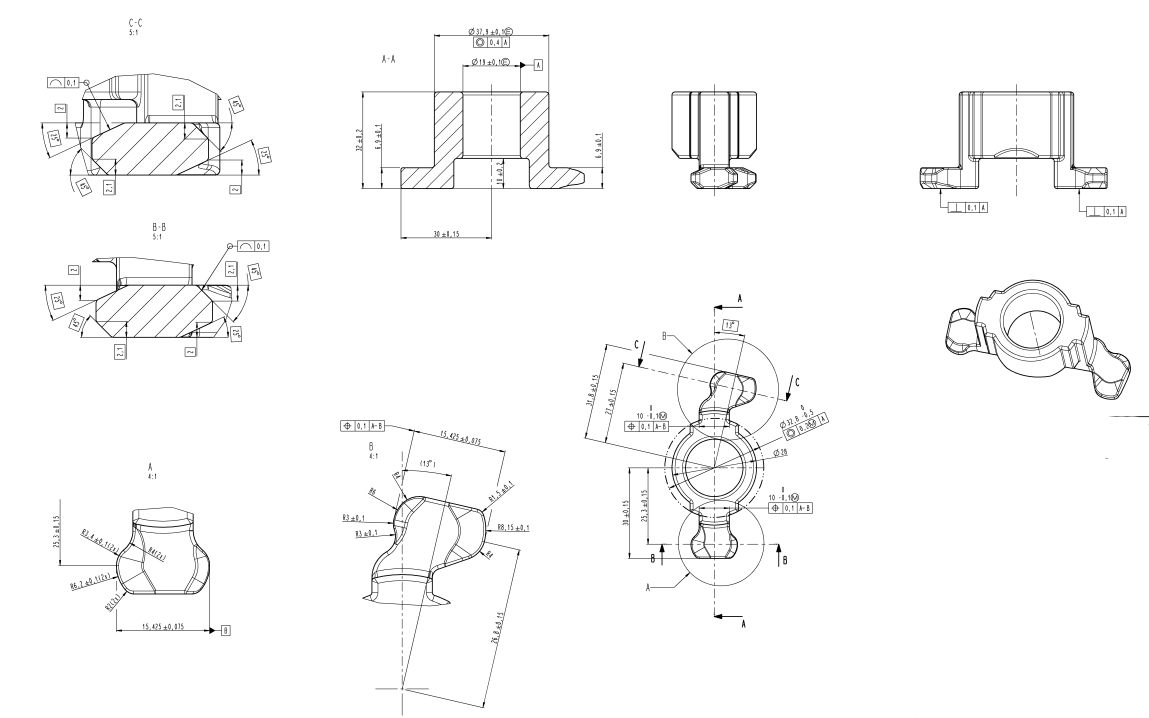

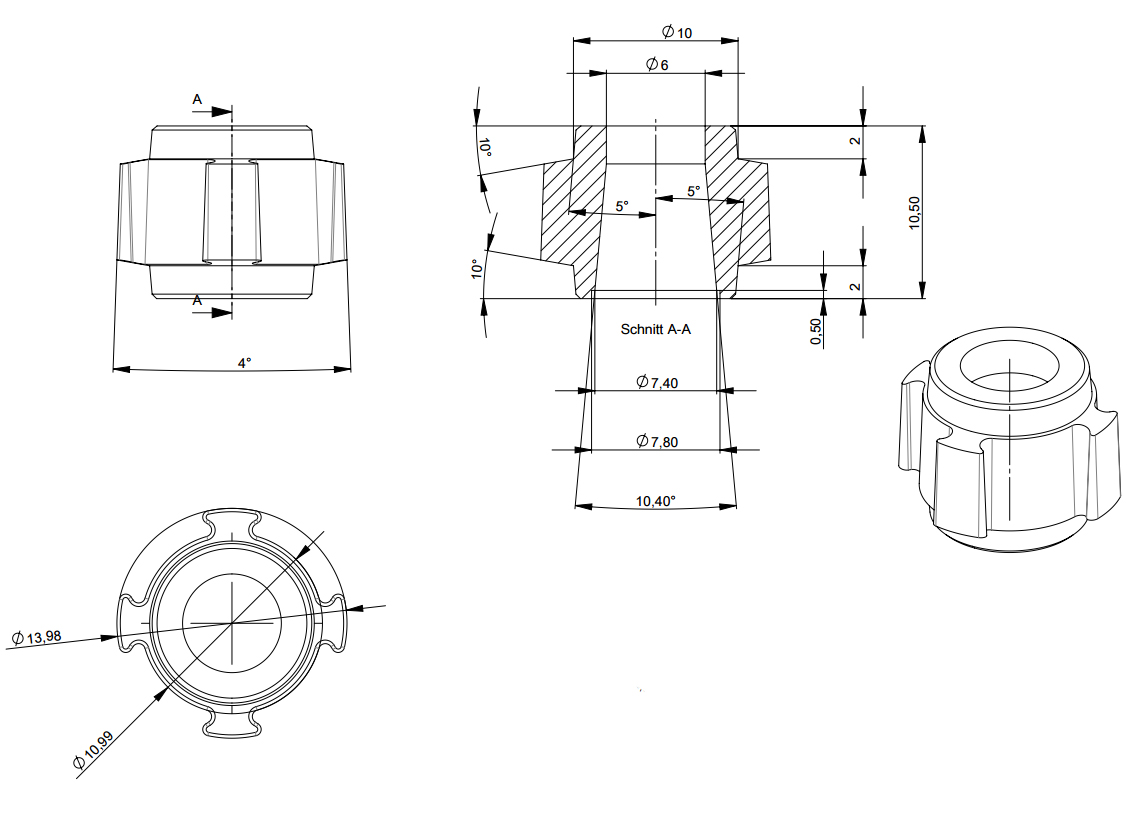

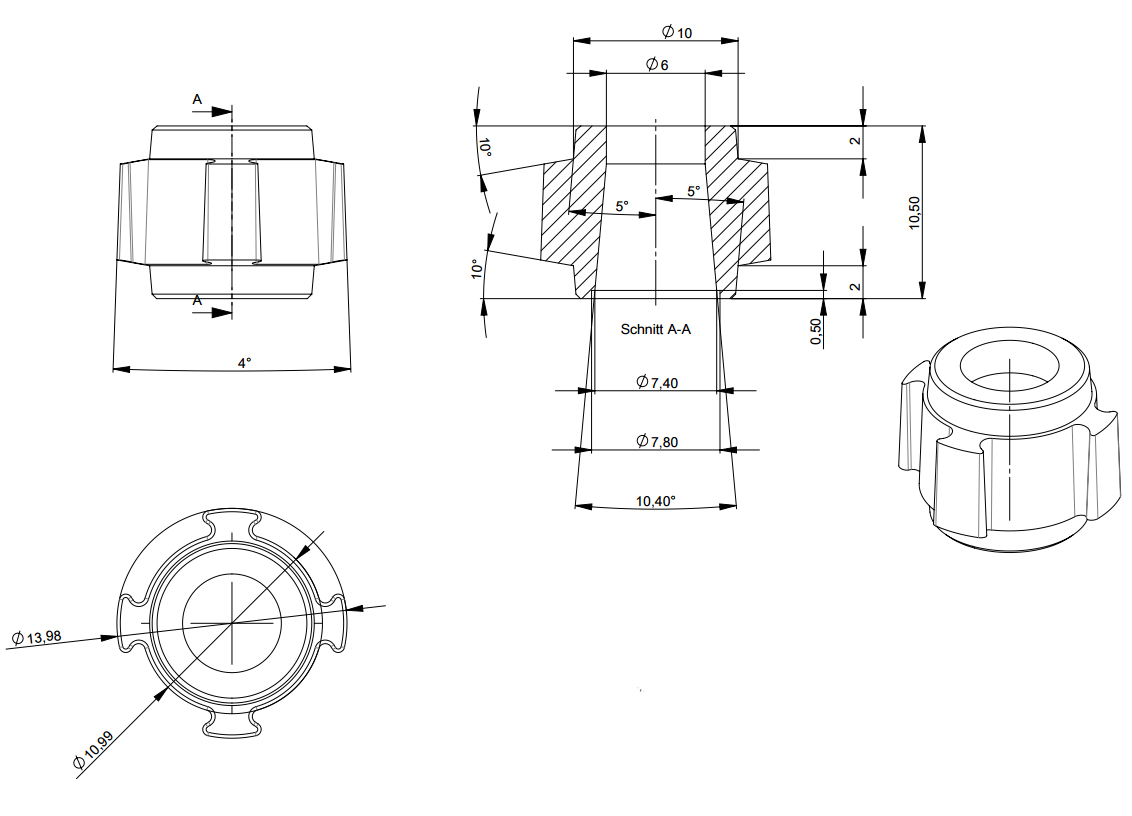

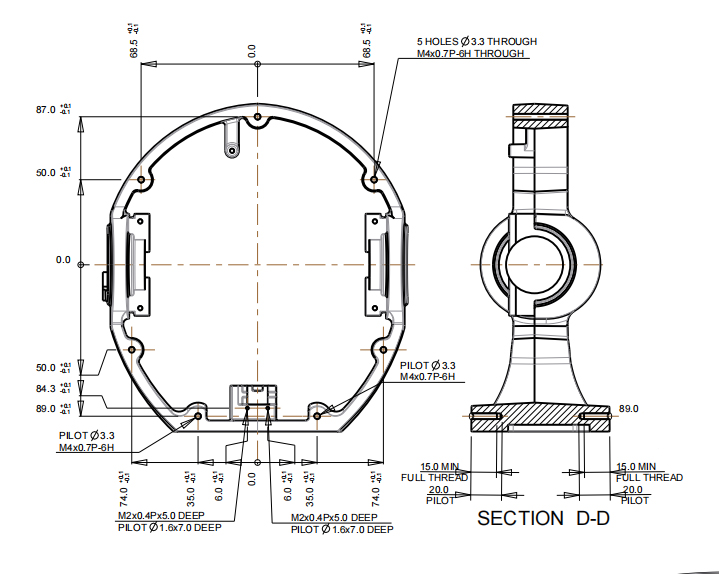

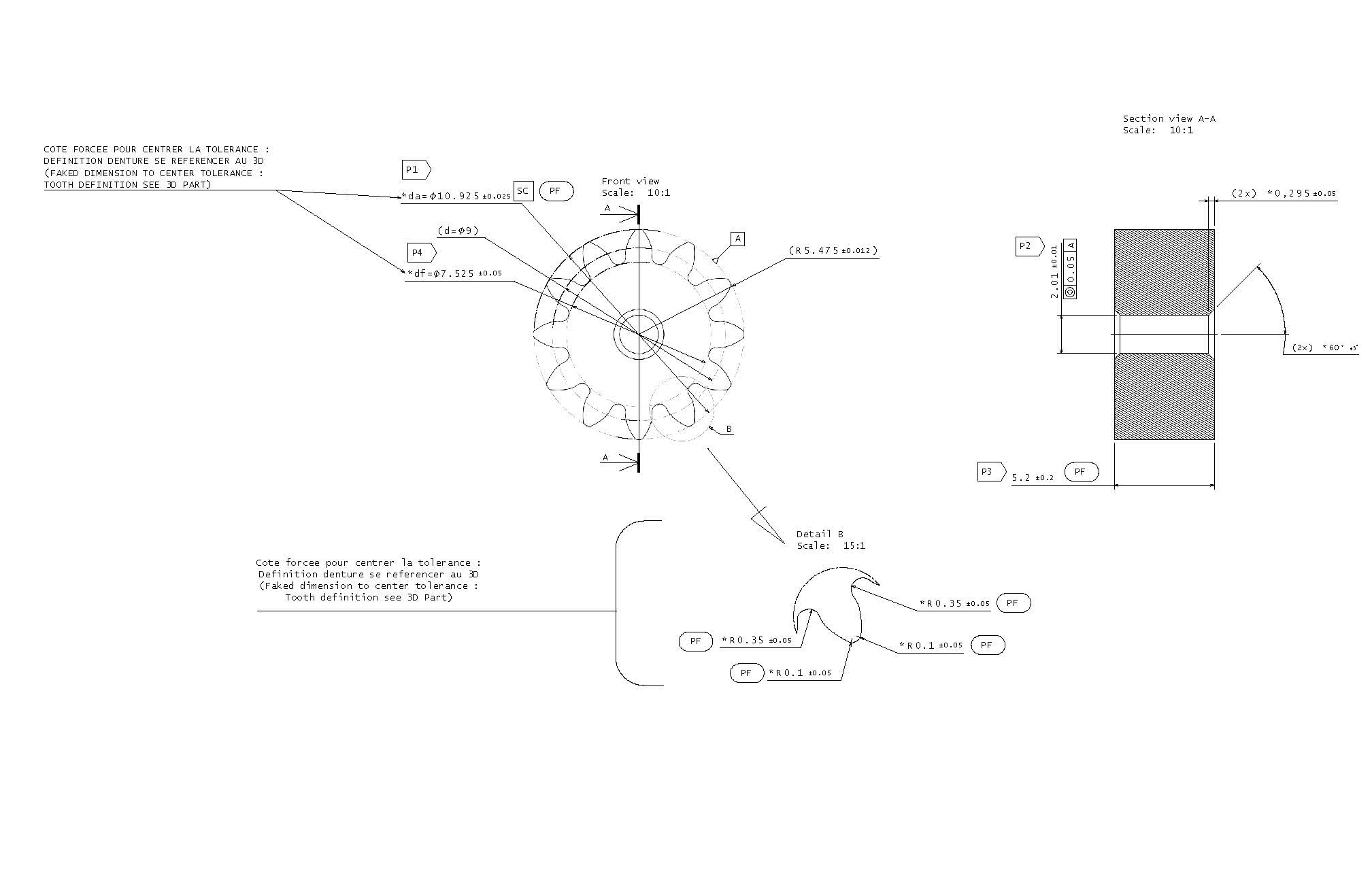

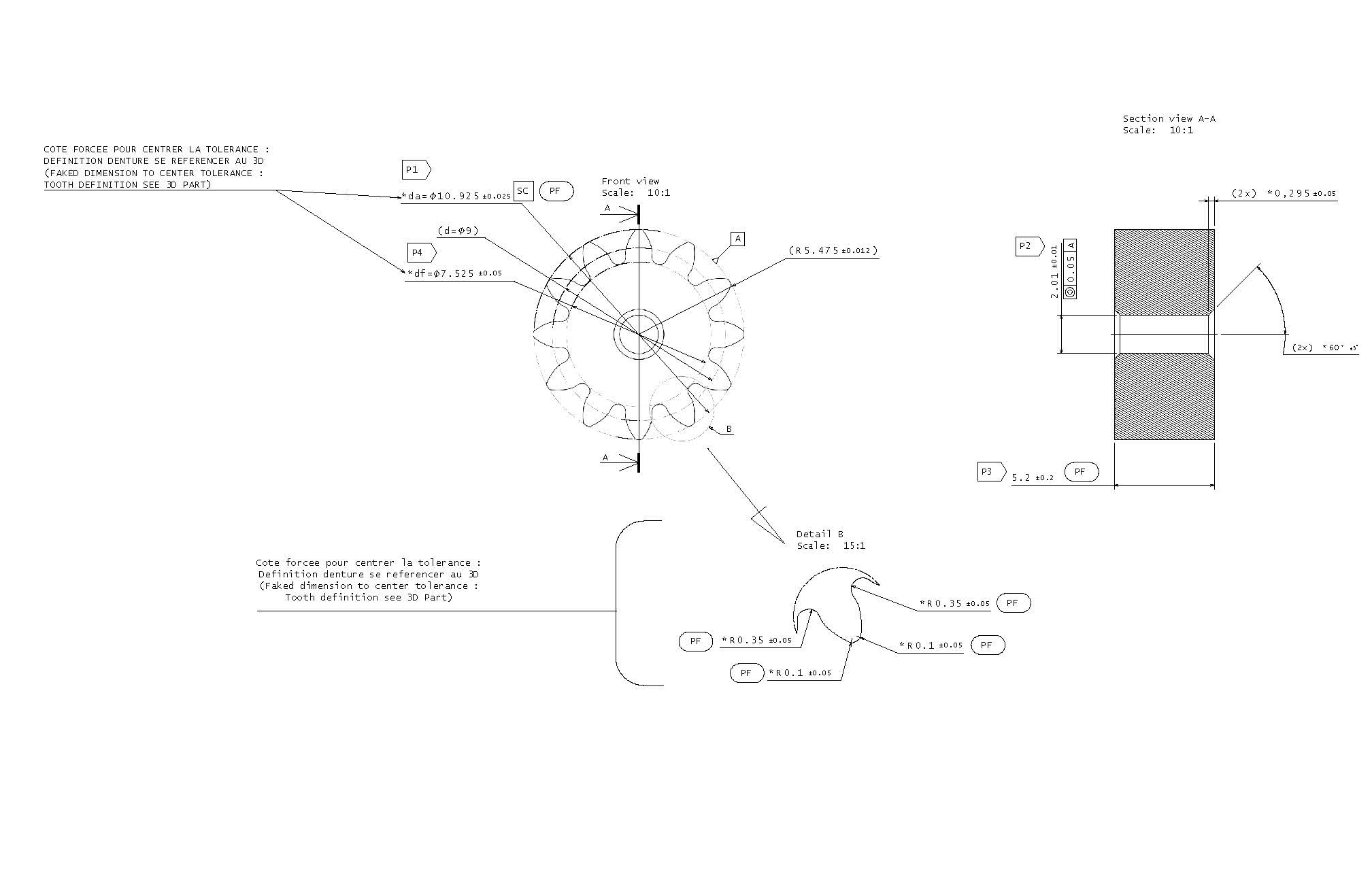

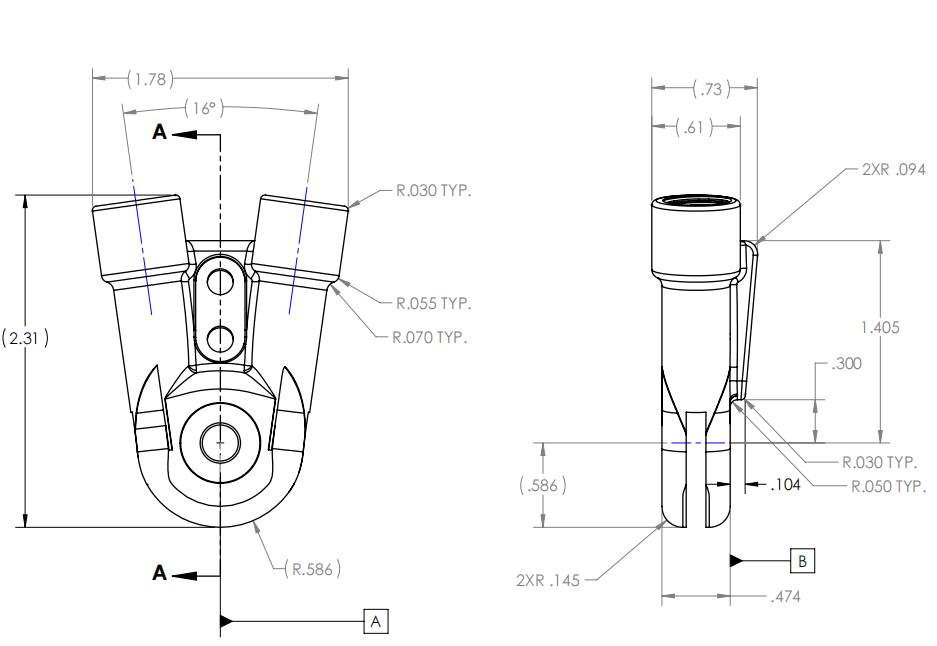

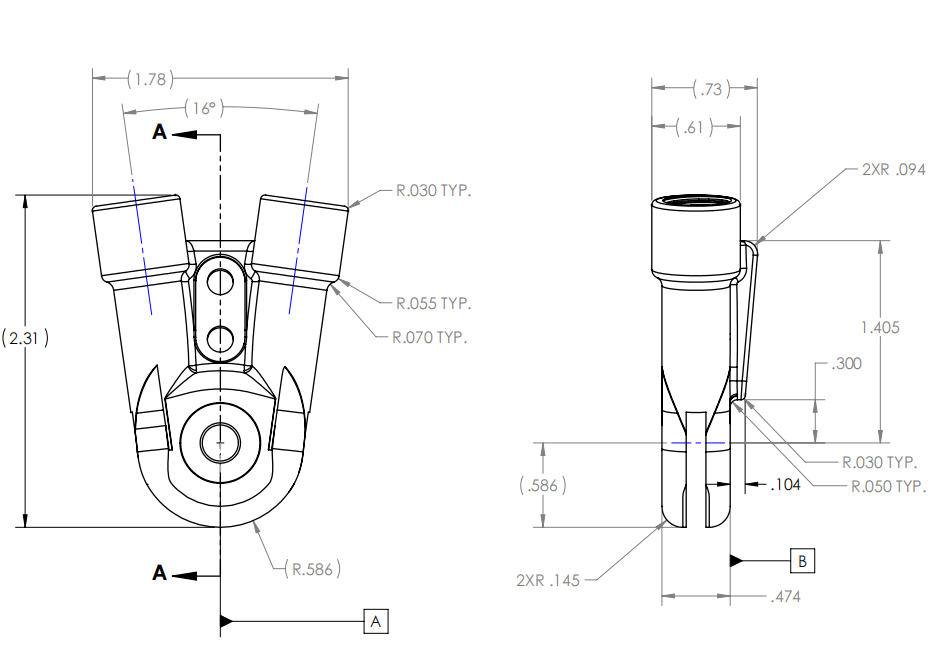

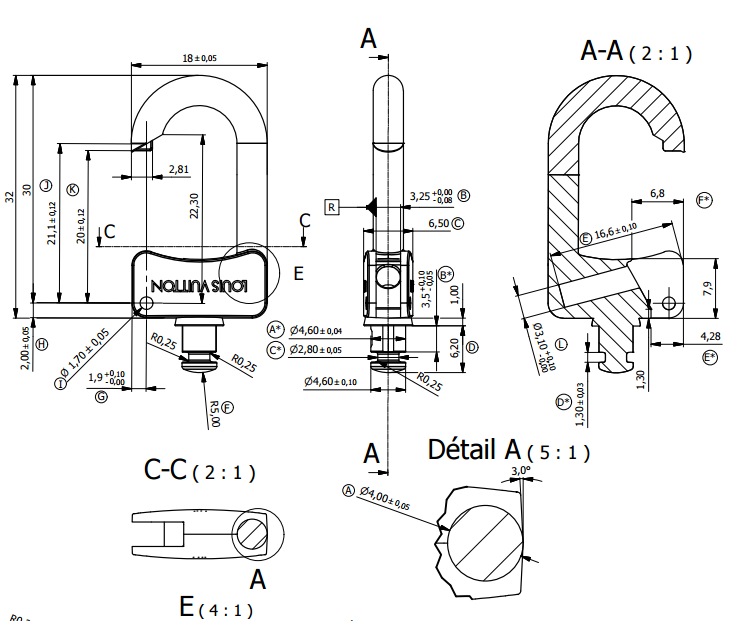

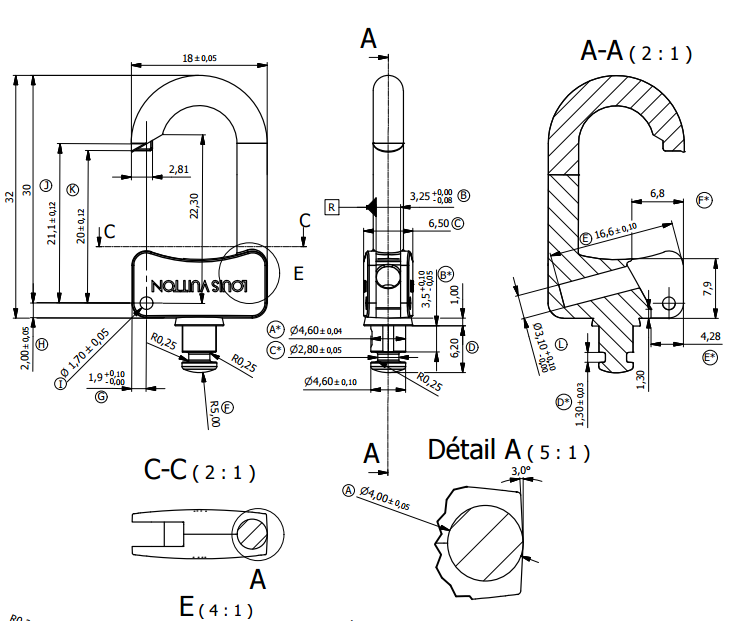

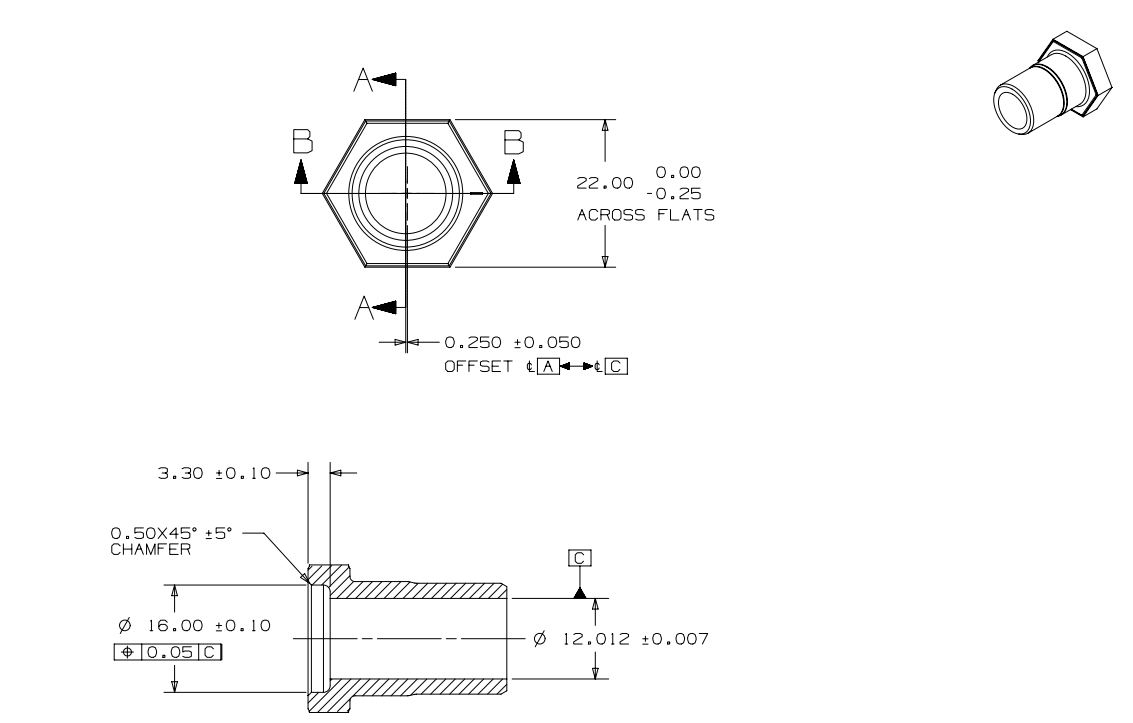

I have studied your website and am now enquiring about quick prototyping of a P/M metal bushing to be used in automobile application for accessory motor. The preliminary drawing and CAD files are attached for your review.

The component is to be produced using the Powder Metallurgy Compaction/Sintering/Impregnation processes.

I will initially require 250 samples for design evaluation. It may be necessary to order additional samples at another time. Once the design is proven, it will be transferred to our high volume serial production motors, beginning in late 2018.

We currently purchase around 5,000 units a year however quantities are steadily increasing and thus it would be beneficial to have quotes based on batch sizes of 1,000, 5,000 and 10,000 off. The material is 316 stainless steel, however we are able to consider alternatives if it aids the reduction of the unit cost, providing corrosion resistance is not negatively affected.

In addition to your quotation could you please include details relating to tolerances that your process can achieve.

Thanks,