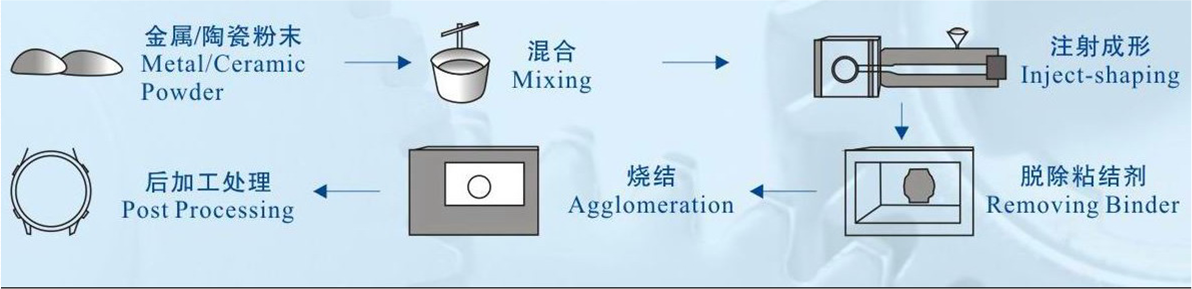

Metal powder precision injection molding is a molding process that combines traditional powder metallurgy and plastic injection molding, also known as MIM (Metal Injection Molding) molding process. Specifically, metal powder and plastic binder are mixed and formed in a mold, and then degreased and sintered to produce metal parts.

Compared with ordinary injection molds, they have some unique features in the design of molded parts, pouring systems, cooling systems, and demolding systems.

In terms of molded parts: 1. The shrinkage rate is different because the parts not only contract during injection molding, but also contract after sintering and degreasing. 2. The demolding angle is different, and MIM injection molds have a large demolding angle, usually taken as 1-3 °. 3. The roughness of the cavity is different, and MIM injection molds are higher than ordinary injection molds. Generally, Ra0.4 is taken. 4. The requirement for material wear resistance is higher because the raw material contains metal powder, which has greater friction and wear on the mold cavity. MIM injection molding parts must be made of wear-resistant steel and undergo quenching or surface nitriding treatment.

Pouring system design: MIM injection molds should use circular cross-section runners as much as possible. Metal powder is a precious metal, and the length of the flow channel should be shortened as much as possible and there should be fewer bends.

Cooling system: The diameter of the cooling water pipe is 2-4 millimeters larger than that of a regular injection mold.

Demolding system: The plasticity and rigidity of the parts are poor, and the layout of the ejection must be sufficient and balanced.

specificities | precision casting | MIM |

Minimum hole diameter | 2mm | 0.4mm |

Maximum depth of blind holes with 2 mm diameter | 2mm | 20mm |

Minimum wall thickness | 2mm | < 1mm |

Maximum wall thickness | limitless | 10mm |

Tolerance for 4mm diameter | ±0.2mm | ±0.06mm |

Surface roughness (Ra) | 5μm | 1μm |

Advantages of powder injection molding:

Like the production of plastic products, a molding production of complex shapes of metals, ceramics and other parts parts of low cost, good finish, high precision (± 0.3% ~ ± 0.1%), generally without subsequent processing of the product strength, hardness, elongation, and other mechanical properties of high, good abrasion resistance, fatigue resistance, organization and uniformity of raw material utilization rate is high, high degree of automation of the production process is simple, can be a large number of consecutive production No pollution, the production process is clean technology production

Powder Injection Molding | |

Material system | Alloy Composition |

low alloy steel | Fe-2Ni,FE-8Ni |

stainless steels | 316L,17-4-PH |

tool steel | 42CrMo4,M2 |

Cemented carbide | WC-Co (6%) |

ceramics | Al2O3,ZrO3,SiO2 |

heavy alloy | W-Ni-Fe, W-Ni-Cu, W-Cu |

Powder Injection Molding Material Applications

Newer MIM material system applications

Application Areas | makings | request |

structural member | high strength steel | Strength >2Gpa |

Medical/Dental | TL Tl-6Al-4V | biocompatibility |

magnetic material | Fe,Fe14Nd2b,SmCo5 | magnetism |

stereo | PZT ceramlcs | frequency response |

Wear parts | ZrO2.WC-Co | Hardness, toughness |

High Temperature Structural Parts | Ni3Al NiAl TiAl | antioxidant |

machining | Al203.SiC,Al203-ZrO2 | dissociation |

heat-resistant body | W.Mo,MOSi2 | crystal growth |

aerospace | superalloy | fatigue period |

Common MIM product applications | |

Aerospace industry aircraft wing strand chains, rocket nozzles, missile tails, ceramic turbine blade cores | |

automobile industry | Ignition control lock parts, turbocharger rotors, valve guide parts, automotive brake parts, automotive anti-technology backbone shed parts |

electronics industry | Disk drive components, cable connectors, electronic housings, computer printheads, electronic packages, heat sinks |

military industry | Mine rotor, gun plate trigger, armor-piercing bullet core, quasi-constellation, cluster arrow bullet tip |

medical care | Dental orthopedic brackets, in vivo sutures, biopsy forceps, kid's radiation screens |

articles for daily use | Watch cases, watch bands, watch buckles, golf heads and seats, sports shoe buckles, sports gun parts, document binding punches |

Machinery Industry | Profile milling cutters, cutting tools, micro gears |

Basic properties of several powder injection molding materials | ||||||

makings | Density 103kg/m3 | durometer | Tensile strength | Bending strength | Elongation % | |

MPa | MPu | |||||

ferrous alloy | MIM4600 | 7.68 | 85HRB | 400 | 25 | |

MIM4650 | 7.68 | 100HRB | 600 | 15 | ||

stainless steels | 316L | 7.94 | 52HRB | 580 | 45 | |

tungsten alloy | 95% W | 18.1 | HRC31 | 930 | 10 | |

97%W | 18.5 | HRC33 | 890 | 6 | ||

Cemented carbide | YG8X | 14.9 | HRA90 | 2300 | ||

Fine Ceramics | Al2O3 | 3.98 | HRA92 | 530 | ||

Comparison of powder injection molding technology with other molding process technology

The powder injection molding process has extremely obvious advantages over traditional batch industries with automated parts processing, stamping, forging, precision casting, and powder metallurgy.

Comparison Program | Powder Injection Molding | powder metallurgy | precision casting | Stamping Machine Processing | punch |

part density | 98% | 86% | 98% | 100% | 100% |

Tensile strength of parts | High | lower | High | High | High |

Surface finish of parts | High | center | center | High | High |

Component Miniaturization Capability | High | center | High | center | High |

Thin-wall capability of parts | High | center | center | High | High |

Complexity of parts | High | lower | center | High | lower |

Part Design Tolerance | High | center | center | center | lower |

batch production capacity | High | High | center | medium-high | High |

Material range | High | High | medium-high | High | center |

delivery capacity | High | High | center | lower | High |

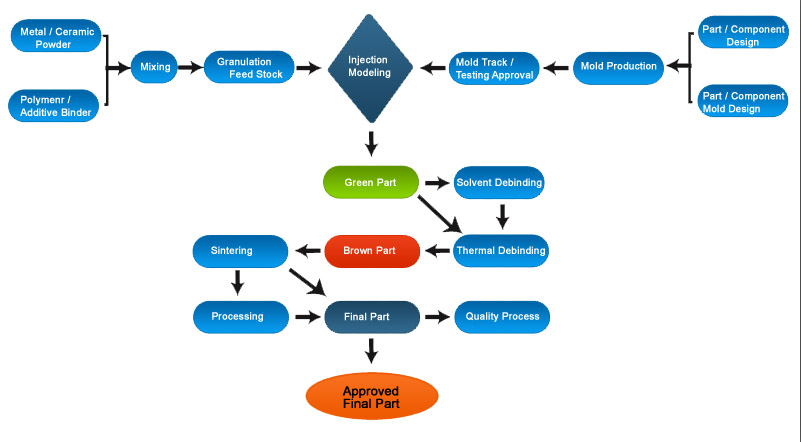

Powder Injection Molding Process Flow Diagram

Please call and email us sales@harber-mim.com and visit us on www.harbermetal.com

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.